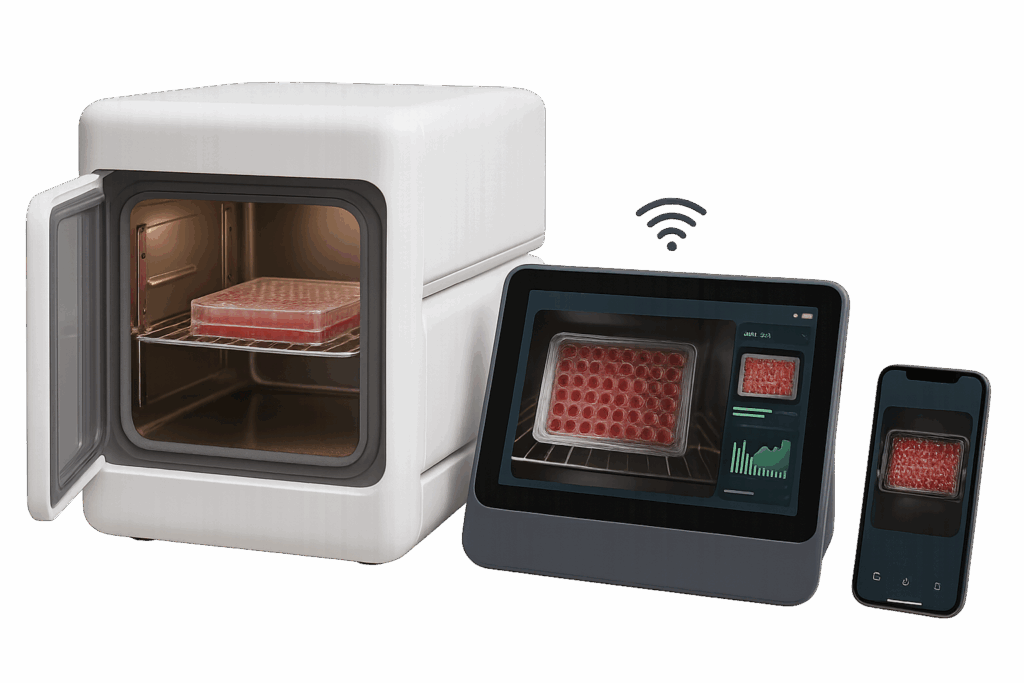

Modular AI Vision Incubator System

A next-generation, modular, camera-enabled incubation platform with built-in AI vision and remote monitoring for modern laboratories, startups, and field labs.

The Modular AI Vision Incubator System is an early-stage concept. Images on this page are visual representations intended to demonstrate the design direction and should not be interpreted as the final production model.

The Problem with Traditional Incubators

Most incubators were designed for a world before automation, AI, and high-throughput experimentation. They limit visibility, flexibility, and data-driven decision making.

Limited Visibility and Control

Experiments run “blind,” with no visibility without opening the door, and no option for remote monitoring or control.

Poor Scalability

Need to purchase separate incubators for new workflows or capacities, which increases the cost and complexity of controlling them separately.

No Integrated Data or AI

Most systems lack built-in imaging, structured data capture, or analytics. That means no automated insight, no trend detection.

Meet the Modular AI Vision Incubator System

A flexible incubation platform that combines modular hardware, high-resolution imaging, and AI-assisted analytics—so your lab can see more, adapt faster, and scale smarter.

Stackable Modular Chambers

Configure and reconfigure multiple chambers for different experiments, capacities, and environmental requirements—all on a single base unit.

Built-in AI Enhanced Imaging

Integrated cameras enable time-lapse imaging and real-time observation and the possibility of application base analysis and prediction.

Stable Environments

Advanced temperature precision, optional high-range humidity control, and both manual and application-based operation ensure stable, uniform, and fully automated incubation conditions.

Remote Monitoring and Control

Control all functionalities remotely and access experiment data, review images, and receive alerts from a web dashboard, enabling true remote and distributed workflows.

Why Choose a Modular AI Vision Incubator?

| Feature | Traditional Incubator | Modular AI Vision Incubator |

|---|---|---|

| Modularity | ✖ Single fixed chamber | ✔ Multi-chamber, stackable modules |

| Imaging | ✖ None or external | ✔ Built-in cameras & time-lapse |

| AI Analytics | ✖ Not available | ✔ Optional AI-assisted insights |

| Remote Monitoring | ✖ Rare / add-on | ✔ Native web dashboard |

| Scalability | ✖ Buy another incubator | ✔ Add chambers and modules |

Designed for Modern Labs

One platform to support microbiology, biotechnology, education, and remote or resource-limited laboratories.

Microbiology & QC

Monitor colony formation, identify contamination earlier, and document growth with rich, visual records.

Biotech & Startups

Adapt your incubation capacity and capabilities as your pipeline evolves—without committing to multiple standalone devices.

Academic & Teaching Labs

Use real-time and time-lapse imagery to enhance teaching, while recording datasets for research and student projects.

Remote & Field Labs

Deploy modular, connected incubation where access is limited, supporting field research and decentralized testing.

Why We Can Build This Device

Our team has engineered and prototyped various types of laboratory instruments for 20 years, including incubators, ovens, centrifuges, chemical and laminar flow hoods, rotator shakers, water baths, and specialized safety equipment. This broad experience ensures we understand both engineering requirements and medical device standards. Furthermore, we are equipped with expertise in modern software technologies and AI.

We know the standards and design incubators to meet international performance benchmarks, achieving:

-

20–80°C temperature range (expandable for refrigerated or R-incubator models)

-

Up to 95% humidity control

-

±0.2°C temperature uniformity under full load

-

PID microprocessor control, Class-A sensors, and dual over-temperature protection

-

316/304 stainless-steel chambers with rounded, easy-clean design

Before prototyping, we perform Finite Element Analysis (FEA), vibration testing, and high-accuracy simulations. All electronics, firmware, and control systems are built in-house, and we integrate AI-enabled monitoring for smarter, safer performance.

By analyzing and understanding the technologies behind top global brands like Siemens, Eppendorf, Memmert, Hitachi, and Mindray, we are able to adapt and integrate their proven engineering approaches into our next-generation incubator.

How You Can Contribute

Our team has strong expertise in mechanical design, prototyping, software implementation, and AI development; however, your contribution is essential in several critical areas.